How to Choose the light floor game manufacturer and supplier in us?

- How to Choose the Right Light Floor Game Manufacturer and Supplier in the US

- Why choosing the right light floor game supplier matters

- Key decision factors when evaluating manufacturers

- 1. Certifications, safety and regulatory compliance

- 2. Hardware quality and component sourcing

- 3. Software, content, and integration support

- 4. Installation, training and local support

- 5. Warranty, spare parts and SLA

- 6. Manufacturing capacity, lead time and MOQ

- 7. Pricing, total cost of ownership and ROI

- 8. Customization and branding capabilities

- 9. Case studies and reference checks

- Comparing supplier types: pros and cons

- Practical procurement checklist and RFP items

- Technical and product requirements

- Service and commercial terms

- Project milestones and acceptance testing

- How Kyda differentiates as a supplier for US projects

- Installation, testing and acceptance: best practices

- Site preparation

- Factory Acceptance Test (FAT)

- Site Acceptance Test (SAT)

- Maintenance strategy and spare parts planning

- Cost vs. value: how to justify the investment

- Checklist summary: essential questions to ask suppliers

- Conclusion

How to Choose the Right Light Floor Game Manufacturer and Supplier in the US

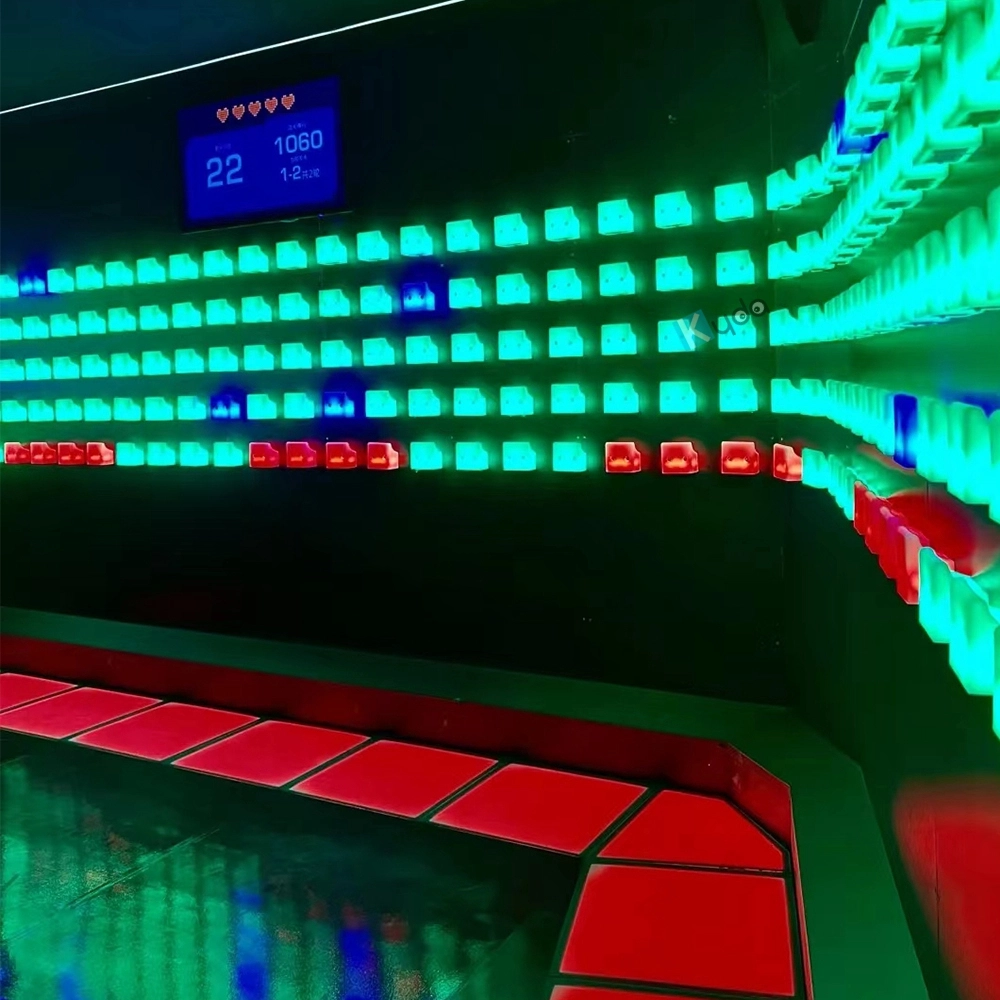

Choosing the right manufacturer and supplier for light floor game systems is critical for operators, entertainment center developers, and buyers who want dependable performance, strong ROI, and a great guest experience. This guide explains the evaluation criteria, procurement steps, technical and commercial considerations, and how Kyda — a one-stop provider of active game rooms and interactive systems — supports US projects through global manufacturing partnerships and local service models.

Why choosing the right light floor game supplier matters

Light floor games combine hardware (LED panels, sensors, controllers), embedded software, animations, and structural elements. Poor supplier choice can lead to long lead times, inconsistent product quality, high maintenance costs, compliance issues, and weak guest engagement. A correct choice reduces downtime, shortens time-to-revenue, and increases lifetime value of the asset.

Key decision factors when evaluating manufacturers

When searching for a light floor game manufacturer or supplier in the US, prioritize the following business- and technical-oriented factors. These directly affect total cost of ownership, uptime, and guest satisfaction.

1. Certifications, safety and regulatory compliance

Electrical and fire safety are non-negotiable for interactive floors that operate in public spaces. Verify that potential suppliers provide:

- UL or ETL listing for electrical safety on finished products or component-level certifications.

- FCC compliance for wireless or radio-enabled controllers (if applicable).

- RoHS and REACH compliance for materials and components.

- Local building-code compatibility and documentation for installation in commercial venues.

Ask for copies of test reports, the exact scope of certification, and whether the product model you buy is covered.

2. Hardware quality and component sourcing

Inspect or request detailed specifications for core components: LED panels, pressure or capacitive sensors, cabling, controllers, and enclosures. Look for:

- Modular panel design for easy replacement and low maintenance cost.

- Trusted LED brands and suppliers, with clear lifetime and brightness specifications.

- Ingress protection and surface durability suitable for high foot-traffic environments.

3. Software, content, and integration support

Light floor games are as much software as hardware. Evaluate supplier capabilities in:

- Pre-built game library and content updates frequency.

- Customization options for animations, scoring, and branding.

- APIs, data export, and integration with POS, membership systems, or analytics tools.

- Remote monitoring, diagnostics, and firmware update mechanisms.

4. Installation, training and local support

Ask whether the supplier provides:

- Turnkey installation with site survey, mechanical works, and final commissioning.

- On-site training for technicians and floor staff.

- Local or regional service partners to reduce Mean Time To Repair (MTTR).

5. Warranty, spare parts and SLA

Warranty and spare parts policy directly affect operational risk. Seek clear terms including:

- Warranty length for electronics, LEDs, and mechanical parts.

- Defined SLAs for on-site repair response times or replacement shipments.

- Availability and pricing of spare panels and controllers.

6. Manufacturing capacity, lead time and MOQ

Confirm the manufacturer’s production capacity and typical lead times. For commercial projects you may require staggered deliveries, pilot units, or multiple locations. Ask about minimum order quantities (MOQs) and ramp-up plans for multi-site rollouts.

7. Pricing, total cost of ownership and ROI

Beyond unit price, calculate TCO: installation, maintenance, spare parts inventory, software licensing, content updates, electricity, and expected uptime. For operators, estimate revenue drivers — increased footfall, session pricing, and repeat play — to calculate payback period. Suppliers experienced in commercial entertainment (like Kyda) can model these scenarios for you.

8. Customization and branding capabilities

Many venues need custom-branded games, unique floor shapes, or tailored content for events. Confirm the supplier’s design pipeline, turnaround for custom animations, and whether custom hardware or bespoke enclosures are feasible.

9. Case studies and reference checks

Ask for case studies in US venues or similar environments. Contact references to verify installation quality, support responsiveness, and long-term reliability.

Comparing supplier types: pros and cons

Below is a concise comparison of typical supplier models you will encounter when sourcing light floor games.

| Supplier Type | Advantages | Risks / Considerations |

|---|---|---|

| US-based Manufacturer / Integrator | Faster service and local support; easier site visits; may meet US procurement rules | Higher unit cost; smaller manufacturing scale; potential longer lead time for complex panels |

| China-based Manufacturer (Direct) | Lower unit costs; large manufacturing capacity; rapid prototyping options | Longer shipping times; customs/import duties; language and coordination gaps; need to verify QC |

| Hybrid / Regional Partner (OEM + Local Service) | Cost-effective production with local installation/support; can balance price and service | Requires strong partner management; vetting of both manufacturer and local integrator |

Kyda operates as a hybrid solution: R&D and design expertise combined with manufacturing partnerships in Guangzhou, Zhongshan, Zhengzhou and Beijing, while supporting global projects with customization and local implementation strategies.

Practical procurement checklist and RFP items

When you issue an RFP or contact suppliers, include these minimum requirements so responses are comparable:

Technical and product requirements

- Detailed BOM (LED type, controller model, sensor type, cabling)

- Mechanical drawings and panel dimensions

- Expected MTBF and LED lumen depreciation rating (e.g., L70 hours)

- Power consumption per square meter and recommended UPS or surge protection

Service and commercial terms

- Warranty details and exclusions

- Spare parts lead times and pricing

- Installation scope, travel costs, and commissioning checklist

- Training and documentation deliverables

Project milestones and acceptance testing

- Prototype acceptance criteria

- Factory Acceptance Test (FAT) and Site Acceptance Test (SAT) procedures

- Penalty clauses or remedies for missed milestones

How Kyda differentiates as a supplier for US projects

Kyda’s strengths address many procurement pain points for US buyers:

- End-to-end capability: from electronics and software design to installation-ready systems.

- Manufacturing partnerships across multiple Chinese production hubs (Guangzhou, Zhongshan, Zhengzhou, Beijing) to optimize cost and capacity.

- Experienced team across hardware, software, animation, and interior design — ensuring coherent product and content delivery.

- Customization for local market needs: hardware adaptations, content localization, and integration with US POS/analytics platforms.

- Support for turnkey projects: site survey, CAD layouts, installation supervision, and training.

For multi-site rollouts, Kyda can provide pilot units, phased deliveries, and spare parts kits to minimize operational risk.

Installation, testing and acceptance: best practices

Site preparation

Ensure the installation area meets mechanical load, flatness and electrical requirements. Typical needs include level flooring, dedicated circuits, and network access for remote diagnostics.

Factory Acceptance Test (FAT)

Before shipping, conduct a FAT where the supplier demonstrates full system functionality, performance under load, network connectivity, and content playback. Verify that the shipped unit matches the RFP BOM.

Site Acceptance Test (SAT)

On-site, verify the game performance under real operating conditions, simulate continuous play, and test recovery after power cycles. Record results and require sign-off to trigger final payment.

Maintenance strategy and spare parts planning

Design a pragmatic maintenance plan that includes:

- On-site spares for commonly replaced items (panel modules, connectors, fuses).

- Remote monitoring subscription to spot failing components before they impact gameplay.

- Training for in-house technicians to perform first-line repairs and basic diagnostics.

Cost vs. value: how to justify the investment

Operators should model revenues from sessions, events, and increased dwell time versus the full cost. Request supplier-provided ROI simulations based on typical utilization for similar venues. A strong supplier will provide reference metrics and realistic uptime assumptions.

Checklist summary: essential questions to ask suppliers

- Can you supply UL/ETL and FCC/EMC reports for this exact model?

- What is the typical lead time from order to ship and earliest pilot availability?

- Do you provide on-site installation and training in my region?

- What warranty terms and spare parts lead times do you offer?

- Can you demonstrate a case study from a similar US venue and provide references?

Conclusion

Selecting a light floor game manufacturer and supplier in the US is a balance between product quality, support capabilities, certifications, and total cost of ownership. Prioritize suppliers that demonstrate technical transparency, provide robust local support options, and can prove their systems in real commercial environments. Kyda’s hybrid model — combining R&D, content design, and manufacturing partnerships — is built to meet customization needs and operational guarantees for commercial entertainment projects. Use the RFP checklist, FAT/SAT procedures, and the comparison table above to make a procurement decision that minimizes risk and maximizes long-term revenue.

References

- UL — Safety Science and Certification. https://www.ul.com/ (Accessed 2024-05-01)

- Federal Communications Commission — Equipment Authorization. https://www.fcc.gov/ (Accessed 2024-04-12)

- European Commission — Restriction of Hazardous Substances (RoHS). https://environment.ec.europa.eu/ (Accessed 2023-11-10)

- ISO — Standards and conformity assessment. https://www.iso.org/ (Accessed 2024-04-20)

- U.S. Small Business Administration — Guide to finding suppliers and procurement basics. https://www.sba.gov/ (Accessed 2024-03-18)

- Consumer Product Safety Commission — Playground and public-use product safety guidance. https://www.cpsc.gov/ (Accessed 2024-02-14)

Note: For specific test reports, ROI models, or to schedule a site survey and pilot unit, contact Kyda’s sales or technical team. Kyda can supply component-level certifications, FAT documentation, and reference installations upon request.

Frequently Asked Questions

What certifications should I insist on for a light floor game?

At minimum, ask for electrical safety certification (UL/ETL) of finished equipment or key components, FCC/EMC compliance for any wireless modules, and RoHS material compliance. Also confirm local building-code compatibility for your venue.

Is it better to buy from a US manufacturer or import from China?

There is no one-size-fits-all answer. US manufacturers often provide faster local support and simpler logistics, while Chinese manufacturers typically offer lower unit costs and larger production capacity. A hybrid model (manufacture abroad, local installation/service) often combines cost-effectiveness with acceptable service levels.

How do I verify a supplier’s manufacturing quality remotely?

Request factory photos, sample videos, third-party test reports, and perform a virtual factory tour. Ask for recent FAT documentation and independent inspection reports. For large projects, plan a physical factory audit or use an inspection agent.

What warranty and spare parts strategy should I require?

Require at least 12 months warranty on electronics and LEDs as a baseline, with spare parts available within defined lead times (e.g., 7–21 days). Define SLA response windows for on-site service and spare shipment priority.

How should I evaluate software and content support?

Confirm the size and update frequency of the game/content library, customization turnaround for branded content, and whether the system supports remote updates and diagnostics. Verify open APIs or integration capabilities if you plan to connect to analytics or POS systems.

Top activate games Manufacturers and Suppliers

Top 10 Active Reaction Games for Training Faster Reflexes

Offline activate games for trade shows and retail activations

How to Choose the activate floor game manufacturer and supplier ?

For Games Grid Floor is Lava

How much size if we start the grid floor is lava?

One LED grid tile is 30*30cm,

Eg: room size 5*5m, which can match 16*16pcs,256pcs for total,

Layout: customize the quantity and place it according to the actual venue.

For Company

Can you customize the game software and hardware?

Yes, Kydaplay accept customize software with hardware.

How many activate game rooms Kydaplay make?

Till now, 50game rooms, still updating new….

Grid, Mega grid, Climb, ARENA ,Control ,HIDE ,Push, Pipes, Laser shooting, Hoops, Cylinder, Octopus,Strike,Flash, Cannon, KNOCK OUT, Lightning, 7 Blocks, GOLDEN GAME BRIDGE, RESTRICTED, BOMB Football, Rotating targets, Angry Bird, GENIUS, Lava Monster, Super Adventure …..

For Activate Gaming Floorislava Family Fun

What is the difference of Grid and Mega Grid?

Grid just interactive floor game, smaller room size can start; Mega Grid add 20pcs Digital screen with 20pcs wall buttons, also need suggest bigger room size, more activate interesting games than Grid;

Can we just buy one game room of Mega grid room?

Yes, If you start the activate game at the first time. We have more than above 50 different activate interactive challenge game rooms for options.

Active Reaction Laser Shooting Game Room

Hoops Active Game: The Ultimate Interactive Basketball Fitness Game

Elevate your basketball skills with Kyda’s Hoops Activate Game, the interactive basketball game. Perfect for basketball game rooms, Activate Hoops offers immersive fitness fun. Experience the Activate Basketball Game that combines sport and technology for active play.

Activate Fitness Climb Game – The Ultimate Interactive LED Climbing Wall Experience

Experience the Activate Fitness Climb Game by Kyda—the interactive LED wall game. This Activate Climb Game combines fitness and fun with dynamic LED challenges, perfect for all ages. Boost agility and engagement with Kyda’s innovative interactive LED wall game today!

7 Blocks Tetris | Kyda Immersive Physical Interactive Game System

The Kyda 7 Blocks Tetris is a cutting-edge, immersive, multiplayer, interactive game that blends physical activity with the timeless excitement of Tetris.

© 2025 Kyda. All Rights Reserved.

Scan QR Code

Scan QR Code

Linkedin

Ins

Facebook

Twitter

YouTube